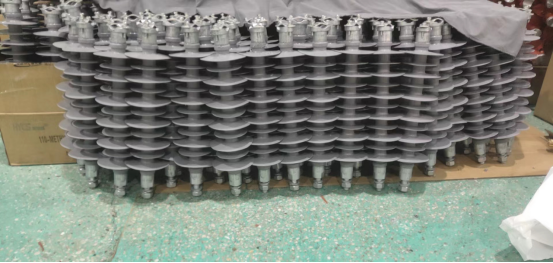

Component of composite pin insulator:

1. The core uses pulling bar made of epoxide reinforced fiber glass, which has good insulation ability, light mass and high intensity and so on.

2. The outer insulation layer is silicon rubber, which formed by high temperature integration pressing and has good sealing ability and high grade of anti-dust, maintenance free and so on.

3. The metal connection adopts pressing technique, which makes the insulator smaller and no damage on the mandrill. It has good sealing ability and is very convenient for installation.

Application for composite insulator:

Polymer pin type insulator is applied to high voltage power line to support conductor and insulate from ground. And composite insulator is used under 36kV distribution line. Since this type insulator has many advantages, now days many countries and areas more and more use this type insulator to displace porcelain or ceramic insulator.

Features of composite pin insulator:

1. The under surface and grooves of sheds or skirts are easy cleaning. Sheds are substantially symmetrical in shape without appreciable warping.

2. The composite pin insulator is suitable for both vertical and horizontal applications. It can be suitable for both bare and protected conductors.

3. This type composite insulators bottom metal end fitting can be suitable for mounting on steel cross arm or wooden cross arm.

4. The top and side grooves can be designed to accept conductor sizes in the range of customers’ requirement.

5. The final color of the insulator housing shall be red or grey.

Composite pin insulator has the following voltage: 11kV, 24kV, 33kV. And different country has different voltage class, it can also called, 10kV, 12kV, 15kV, 20kV, 22kV, 35kV, 36kV.

The strength of polymer pin type insulator: 6kN, 8kN, 10kN, 12.5kN

we can also produce totally in accordance with customer’s requirement.

Specifications

Type | Rated voltage (KV) | Specifified bending load | Section length (mm) | Min Arc distance (mm) | Leakage distance (mm) | Lightning impulse withstand BIL(KV) | Power frequency withstand (wet) (KV) |

FPQ-11/4 | 11 | 4 | 285 | 205 | 450 | 105 | 45 |

FPQ-11/5 | 11 | 5 | 300 | 220 | 480 | 105 | 45 |

FPQ-11/5 | 11 | 5 | 245 | 177 | 426 | 105 | 45 |

FPQ-11/10 | 11 | 10 | 276 | 191 | 525 | 105 | 45 |

FPQ-15/10 | 15 | 10 | 280 | 160 | 660 | 145 | 65 |

FPQ-24/8 | 24 | 8 | 260 | 180 | 770 | 185 | 80 |

FPQ-24/12.5 | 24 | 12.5 | 300 | 185 | 700 | 185 | 80 |

FPQ-33/10 | 33 | 10 | 335 | 250 | 740 | 185 | 80 |

FPQ-33/12.5 | 33 | 12.5 | 430 | 340 | 1080 | 230 | 95 |

FPQ-33/6 | 33 | 6 | 490 | 380 | 880 | 200 | 95 |

FPQ-35/5 | 35 | 5 | 540 | 375 | 1185 | 230 | 95 |

FPQ-36/12.5 | 36 | 12.5 | 600 | 530 | 1440 | 325 | 140 |

We can customize products according to | |||||||